Gas steam boiler principle: The gas steam boiler is a heat energy conversion device that uses natural gas, liquefied gas, city gas and other gas fuels as fuel, burns the heat released in the furnace, heats the water in the boiler, and vaporizes it into steam. The water in the pot (tube) is continuously heated by the energy released by the combustion of the gas fuel in the furnace. The temperature rises and generates steam under pressure. Since the boiling point of water rises with the increase of pressure, the pot is sealed and the steam The expansion inside is limited to generate pressure to form thermodynamic power (strictly speaking, the water vapor of the boiler is formed by heating the water at a constant pressure in the drum until the saturated water is re-vaporized). It is widely used as an energy source.

The boiler is mainly composed of the main body of the boiler shell and the furnace bladder, accessories to ensure its safe and economic continuous operation, auxiliary equipment for the instrument, automatic control and protection system, etc. This boiler is a drum-type boiler with a water-cooled wall, and two return fireworks are arranged in the left and right sections of the drum, which are folded back in the front smoke box at the front of the drum. Between the boiler tube and the lower connecting box, there is a down comer and a water-cooled tube to form the frame of the combustion chamber. There is a steam-water separator in the upper part of the drum to reduce the water brought out by the steam. The heating surface of the pot body is the lower part of the pot barrel, the water-cooled wall tube and the pyrotechnic tube.

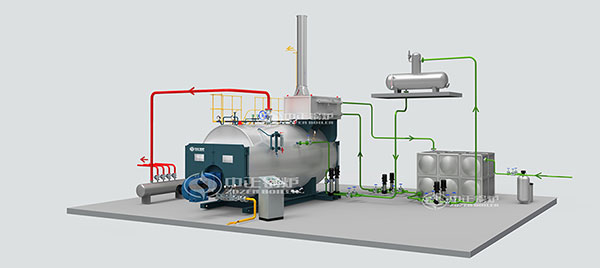

The basic components of steam boiler and its working principle The steam boiler is composed of a series of equipment, which can be roughly divided into two parts: main components and auxiliary equipment.

The main components of the boiler are:

- Furnace: ensure that the fuel of the boiler is burned out and the temperature of the outlet flue gas is cooled to a value where the convection heating surface can work safely;

- Economizer: The heat of the flue gas in the tail of the boiler is used to heat the feed water to reduce the temperature of flue gas and save fuel.

- Boiler: Connect the heating surfaces of the boiler together with the water cooling wall and down comer to form a water circulation circuit. The drum stores the soda water, which can adapt to the load changes. There is a steam-water separation device inside to ensure the quality of the soda water. The once-through boiler has no drum.

- Water-cooled wall: The main radiation heating surface of the boiler, which absorbs the radiation of the furnace, heats the working medium, protects the furnace wall, etc.

- Combustion equipment: send fuel and air required for combustion into the furnace and make the fuel ignite stably and burn well.

- Air preheater: Heat the air for fuel to enhance ignition and combustion, absorb the waste heat of flue gas, reduce the temperature of flue gas, and improve the efficiency of the boiler.

- Furnace wall: it is the protective shell of the boiler, which plays the role of sealing and heat preservation. The heavy-duty furnace wall of a small boiler can also serve as a support for boiler components.

- Framework: supporting and fixing boiler components.

The auxiliary equipment of the boiler mainly includes:

- Air-inducing equipment: the flue gas in the operation of the boiler is sent to the atmosphere through the induced draft fan and chimney

- Dust removal equipment: remove fly ash from boiler flue gas.

- Fuel supply equipment: storage and transportation of fuel

- Water supply equipment: the feed water processed by the water treatment equipment is sent to the boiler by the water supply pump

- Dust and slag removal equipment: remove ash and slag from the boiler and transport away.

- Air supply equipment: The air heated by the air preheater is sent to the furnace and coal grinding device through the air blower.

- Automatic control equipment: automatic detection, program control, automatic protection and automatic adjustment.

LEAVE A MESSAGE

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.

Thanks for your subsmission! ZOZEN sales managers will contact you within 48 hours. Please check your email or whatsapp in time. If you do not receive the email in your normal inbox, please check your spam mail folder.